The corrugated cardboard box is the backbone of logistics and e-commerce, yet few know the fascinating and efficient process that creates it. Its journey begins with sustainable raw material: paper pulp, often sourced from recycled fibers. Understanding this manufacturing process not only reveals the box’s strength but also its commitment to recycling and sustainability.

Step 1: Sheet Creation and the “Corrugator”

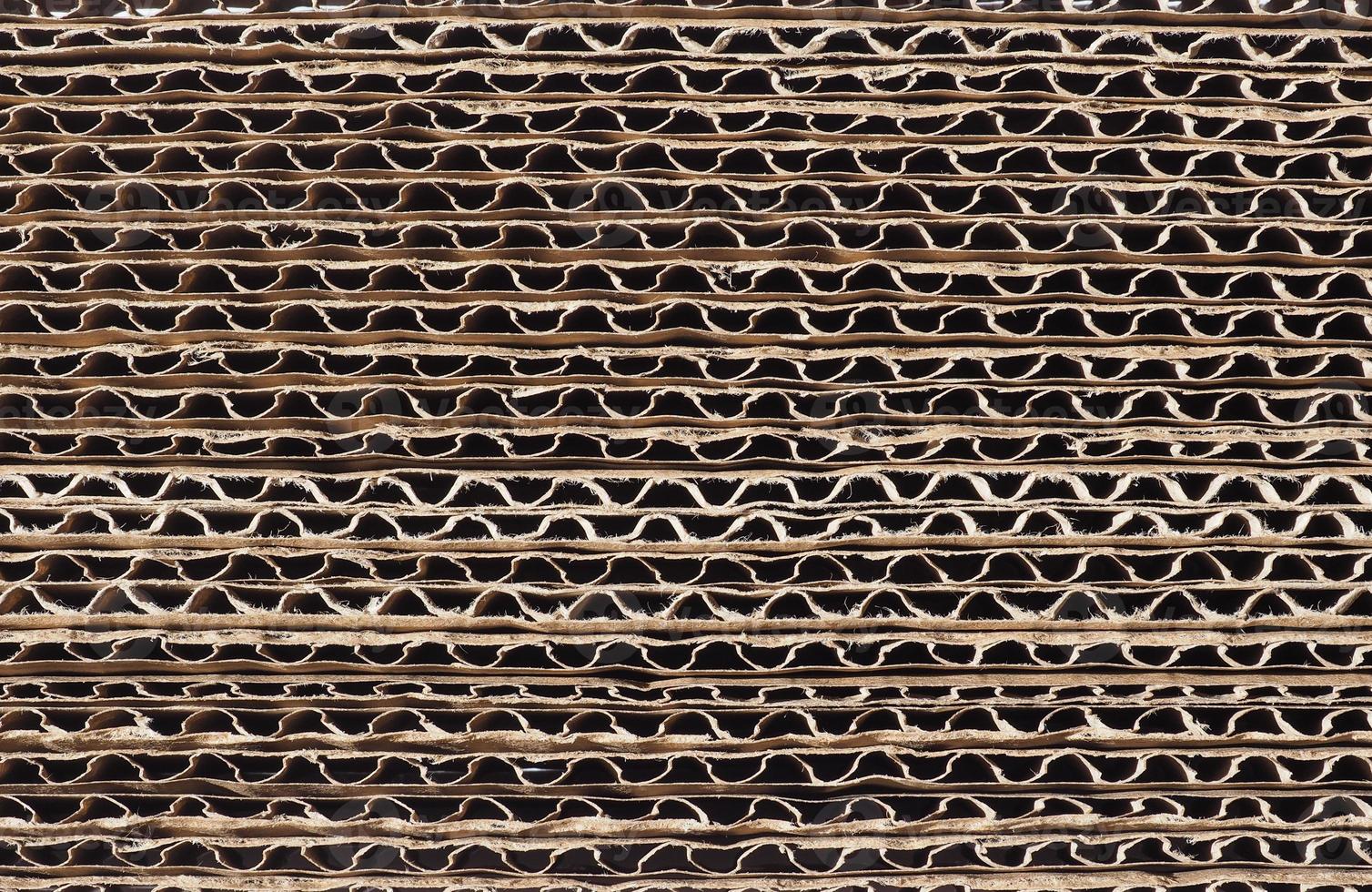

The process starts at the corrugating machine, the factory’s heart. Here, large rolls of flat paper are unwound. Three types of paper are used: two outer layers (the liners) and an inner layer, known as the flute or wave. This flute passes through hot, grooved rollers that give it its characteristic wavy shape, which is responsible for cushioning and strength.

Step 2: Gluing (Joining the Layers)

Once the paper is corrugated, a natural, starch-based adhesive is applied to the flute’s crests. Immediately, the wavy layer is pressed between the two flat liner layers. This union forms the characteristic three-layer sandwich (or more, in the case of double or triple wall corrugated), creating the corrugated cardboard panel.

Step 3: Cutting and Scoring

The massive cardboard sheet moves to the cutting station. It is cut transversely to define the width and longitudinally for the length. Simultaneously, the scores or creases are created. These essential grooves allow the box to fold cleanly and precisely, preparing it for its final shape.

Step 4: Printing and Die-Cutting

If the box requires branding or instructions (like “Fragile”), it is printed before or after the cutting stage. The panel then passes through a die-cutting machine that performs the complex cuts, such as the flaps and perforations, defining the box style (e.g., Regular Slotted Container or RSC type).

Conclusion: From Fiber to Function

The final step involves folding and often gluing the side joint tab so the box can be shipped flat (knocked-down). The cycle is complete: a strong box is born from sustainable pulp, protecting goods in transit and ensuring efficient packaging. Corrugated cardboard is not just a material; it is an engineering marvel of protection serving the modern world.

With Cyecsa / Kibox, you will have the peace of mind that you are working with a company that cares ecologically, socially, and economically.

If you want more information, connect with us via Kibot for a personalized consultation