In a market where brands compete to capture attention within seconds, print quality on corrugated cardboard has become a decisive factor. Two technologies stand out for their visual impact and performance: water-based digital printing and metallic finishes. Although both offer attractive results, their advantages, limitations, and costs can make a significant difference in how well a package or display performs at the point of sale.

Water-Based Digital Printing: Efficiency, Quality, and Sustainability

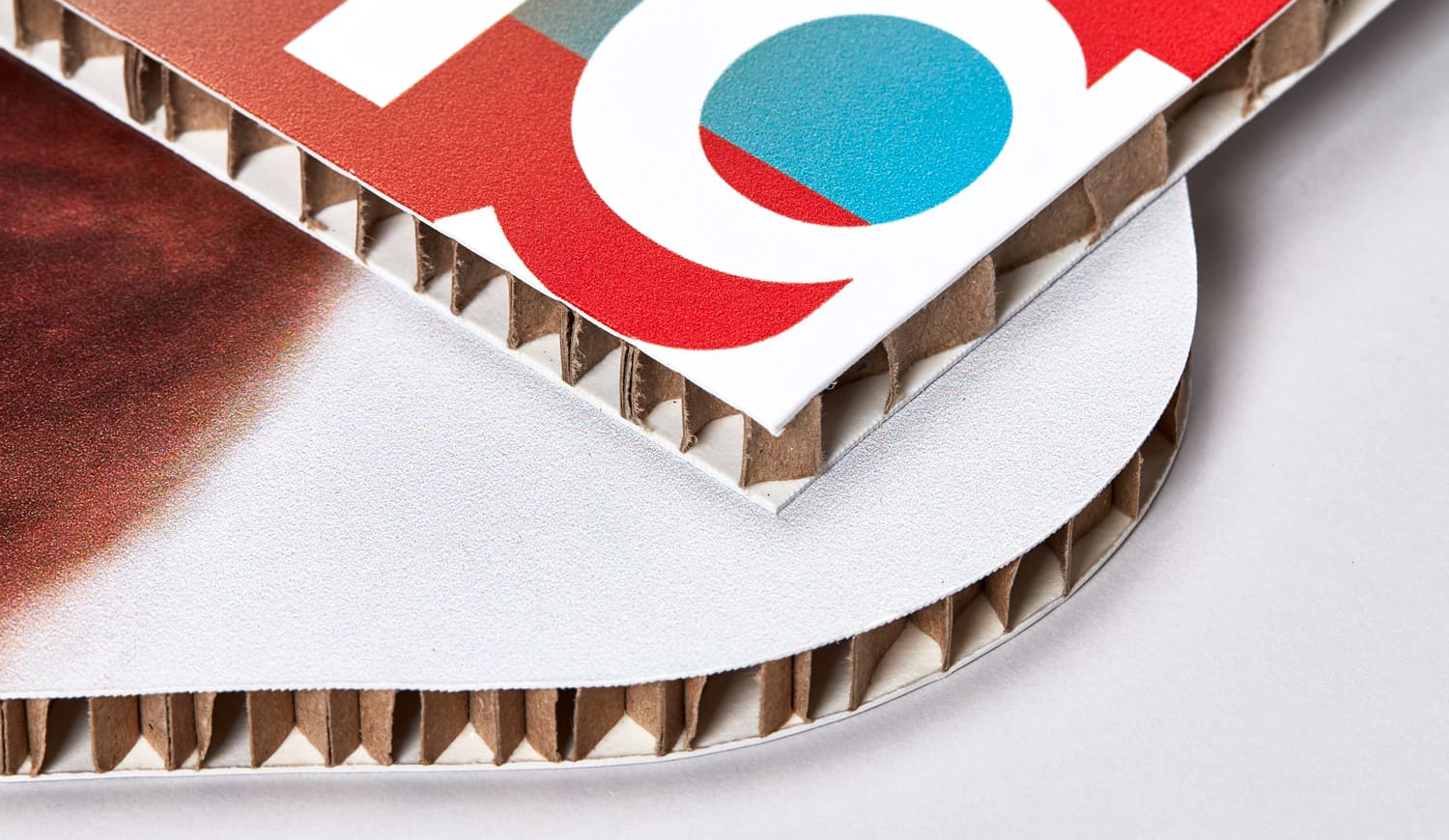

Water-based digital printing has become one of the most in-demand solutions in the packaging industry thanks to its versatility, high image quality, and fast turnaround. Its solvent-free inks deliver vibrant colors, crisp details, and strong fidelity even on corrugated surfaces.

One of its greatest strengths is that it requires no plates or complex prepress processes, reducing lead times and costs—especially for short runs or customized projects. This makes it the ideal technology for prototypes, seasonal campaigns, limited editions, and personalized packaging.

Water-based printing also stands out for its eco-friendly profile. The inks generate less waste, facilitate cardboard recycling, and comply with food-safe packaging standards, making it particularly appealing for brands with sustainability goals.

Metallic Printing: A Premium Visual Impact

Metallic finishes remain a valuable option for brands seeking a premium look with high reflectivity and eye-catching shine. These effects are achieved through foils, hot stamping, or laminated films that deliver mirror-like, reflective, and luxurious surfaces.

This technique is ideal for categories such as cosmetics, electronics, luxury goods, spirits, or promotional products that require a sophisticated visual appeal. However, metallic printing involves longer, more complex, and more expensive processes. It requires additional materials, preparation time, and offers less flexibility for updates or personalization on large-volume projects.

Despite its visual appeal, metallic finishing tends to be less sustainable, as the added plastic films can hinder the recyclability of corrugated cardboard. Costs are also higher due to the extra steps and materials required.

Which Technology Should You Choose?

The decision depends directly on your brand goals, budget, and product category.

- If you need speed, customization, cost efficiency on short runs, or eco-friendly solutions, water-based digital printing is the best option.

- If your priority is projecting a high-end, ultra-premium look with unique reflective effects, metallic finishing remains the top choice.

Many brands even combine both technologies to balance cost and aesthetics—using water-based printing for most of the packaging and reserving metallic accents for high-impact design elements.

Conclusion

Both water-based digital printing and metallic finishes play a key role in modern packaging. The key is to evaluate your project’s visual, functional, economic, and environmental needs. Understanding the strengths of each technology will help you create packaging that is more strategic, visually compelling, and aligned with your target market.

With Cyecsa / Kibox, you will have the peace of mind that you are working with a company that cares ecologically, socially, and economically.

If you want more information, connect with us via Kibot for a personalized consultation